Selection of Catalysts

Reasonable selection and use of catalysts can make some reactions that are not easy to occur relatively feasible.

We provide different types of catalysts for you to test and use. Most of the time, this chanllenge job is done as the result of optimization and selection under the joint participation and guidance of our senior catalyst experts, which makes the comprehensive performance of the catalyst have certain advantages, such as balancing the activity and selectivity of the reaction, controlling a better yield and effectively inhibiting the occurrence of side reactions, the reaction conditions (duration, space velocity, temperature, pressure, etc.) are improved, the needs of commercial mass production are taken into account, and even the time of filtration and separation, the cost of purification, the turnover number the catalyst, and the situation that catalyst deactivation, metal loss are not easy to occur or at an acceptalbe level.

We provide different types of catalysts for you to test and use. Most of the time, this chanllenge job is done as the result of optimization and selection under the joint participation and guidance of our senior catalyst experts, which makes the comprehensive performance of the catalyst have certain advantages, such as balancing the activity and selectivity of the reaction, controlling a better yield and effectively inhibiting the occurrence of side reactions, the reaction conditions (duration, space velocity, temperature, pressure, etc.) are improved, the needs of commercial mass production are taken into account, and even the time of filtration and separation, the cost of purification, the turnover number the catalyst, and the situation that catalyst deactivation, metal loss are not easy to occur or at an acceptalbe level.

The following is a collection of some commonly used reaction types. Our catalyst experts are well aware of the importance of theoretical guidance, but in fact they do not stick to theory, but prefer practice and performance function. Catalyst technology is a multidisciplinary technology. Many times the correct metal type is selected, but the slight difference in performance is actually due to the difference in preparation methods and technologies when preparation of catalysts, the resulting performance of the catalyst is actually the result of the interaction of the metal with the support material or ligand in the event of homogeneous catalysts.

Generally applicable to the reaction type of precious metal on the supported material::

- ► Hydrogenation Reaction

- ► Reductive Amination/Alkylation Reaction

- ► Hydrocracking Reaction

- ► Dehalogenation Reaction

- ► Disproportionation Reaction

- ► Dehydrogenation Reaction

- ► Degradation Reaction.

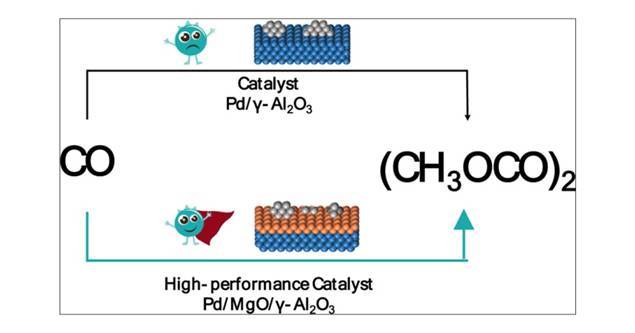

- ► Carbonylation Reaction

- ► Oxidation Reaction

- ► Acetoxylation Reaction

- ► Hydrosilylation Reaction